Co-Product Utilization

Co-products will be generated in the biomass to algal oil process that have potential to add value to the commercial process.

Energy Generation of Lignin through Liquefaction and Fischer-Tropsch Process

Research projects have been initiated to generate liquid fuels and useful chemicals from lignin, a by-product resulting from the biomass to biofuel process. The projects aim to discover the best reaction conditions (temperature, pressure and solvents) for the utilization of lignin and to find active, stable, and selective catalysts which can be used in the Fischer-Tropsch process.

Lignin is a complex polymer of phenylpropyl units, which are cross-linked to each other with a variety of different chemical bonds. Among the three major polymers within biomass, cellulose, lignin, and hemicelluloses, the lignin is the least utilized component. During the process of producing biofuel through a transesterification of lipids in algae, a significant amount of lignin is produced, which could pose a potential disposal liability. To turn this liability into an opportunity, combining lignin liquefaction and gasification with Fischer-Tropsch technology would prodcue additional source of biofuel for market.

Ionic Liquids for Lignin Utilization

Dr. Laurel Morton & Dr. Darrin Smith

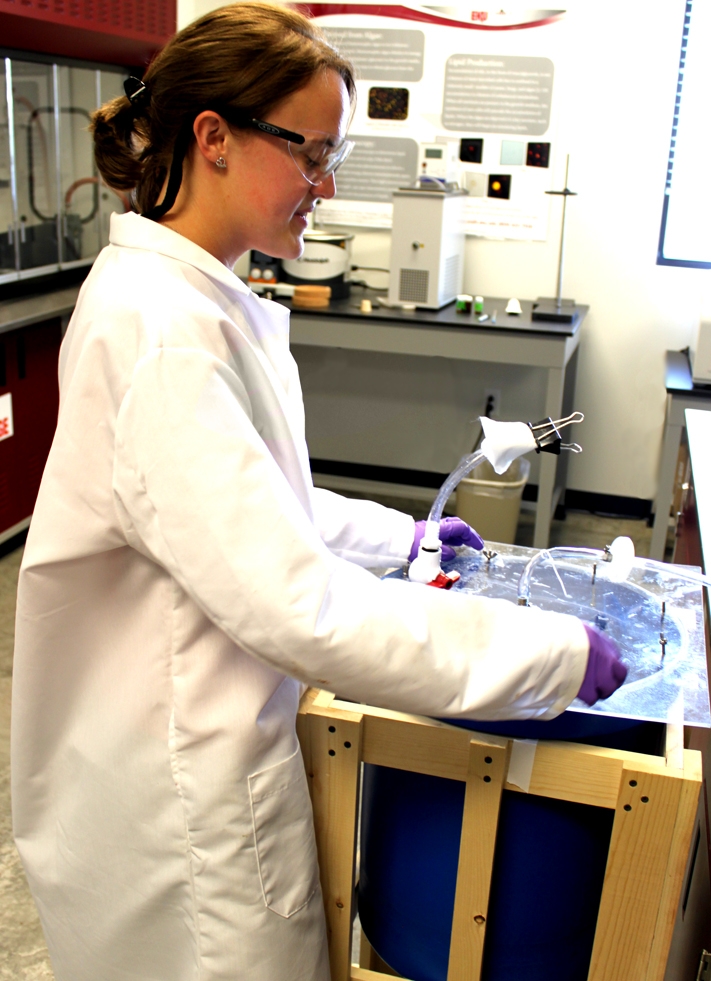

The utilization of ionic liquids as unique, environmentally friendly solvents for the dissolution of lignin for production of useful chemical components for industrial uses have been initiated. Ionic liquids have received much attention for their ability to dissolve lignin and cellulose and by incorporating a catalyst into the system chemically it is hoped to alleviate catalyst loss and improve processing.

The primary limitation to the utilization of lignocellulosic biomass (cellulose, hemicellulose, and lignin) is the difficulty in converting the components to usable feedstocks for biofuels and bioproducts. While lignocellulosic materials can be transformed via enzymatic degradation, the enzymes required have limited functionality under the conditions required to effectively dissolve lignin and cellulose. As a result, the utilization of the lignin fraction as a primary bio-resource has yet to be achieved commercially, and as such has relegated its use to merely that of a co-firing combustion feedstock.

The development of new methods for the full utilization of lignocellulosic biomass must address the challenge of "biomass recalcitrance" - the natural resistance plant matter exhibits to biodegradation. Current methods for delignification, including oxidation, hydrogenolysis, mild hydrolysis, and acidolysis, involve economically and energetically unsustainable processes utilizing enzymes or traditional chemical routes that employ harsh process conditions that generate both economic and environmental challenges. Therefore, more energy efficient and environmentally friendly methods of delignification for the processing of lignocellulosic materials yielding valuable bioproducts (biopolymers, biofuels, commodity chemicals, etc) are needed.

Utilization of Furans as Renewable Building Blocks

This project will research the conversion of furans from biomass products into value added chemicals and materials for the biorefinery and renewable energy sector. Th is process will explore the chemical transformations of biomass to sugar byproducts, such as furfural, into precursors of renewable building blocks for plastics, polymers, and advanced electronics.

With the increasing demand of petroleum continuing to negatively influence the United States economy and security, transitioning to renewable fuels and high value chemicals has become a high priority in the sciences. While Biofuels have been given a large amount of attention, replacement of petroleum-based materials (e.g., plastics) is just as critical. Recent advances in carbohydrate research have shown that furans (5-membered ringed compounds which contain one oxygen) represent a truly renewable building block for high value materials. These renewable compounds have the potential to be incorporated into next generation electronics (e.g., integrated circuits, flat screen monitors, thin film solar cells), plastics and resins, and synthetics fibers, all at a fraction of the price of traditional materials. The goal of the proposed research is to develop novel synthetic routes to value added chemicals from furans. To stress the “green” emphasis of the project, the initial investigation would begin with the purchase of commercially available furans which can be formed directly and catalytically from carbohydrates. Thus, the project would focus on the downstream development of high value chemicals in the Biorefinery sector.

Evaluation of Algal Meal for Livestock Feed

Agal meal or the "left overs" after bio oils are extracted from algae have potential to be utilized as a protein-rich livestock feed supplement. A commercial algal oil facility would generate hundreds of tons of algae meal and provide an alternative source of feed for livestock producers.